Introduction

When choosing paper, besides colored options, the most common colors you'll find are white and kraft brown. This is because white paper is made from bleached pulp, while kraft-colored paper comes from unbleached pulp. Do you know the difference between them? Don't worry, in this article, I'll explain their differences based on manufacturing process, color, lignin content, environmental impact, and typical uses. Keep reading if you want to learn more!

What Is Pulp?

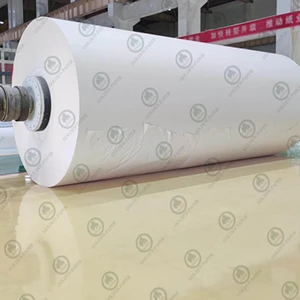

Pulp is the raw material used to make paper, derived from wood. Whether you need office paper, packaging board, printing paper, food packaging paper, or tissue paper, it all starts with pulp. Essentially, pulp is a fibrous semi-finished product made by breaking down wood, bamboo, or other plant fibers. The key components of pulp are cellulose and hemicellulose. The color of pulp can be white or brown depending on whether it has been bleached.

Differences Between Bleached and Unbleached Pulp

Manufacturing Process

Bleached pulp goes through additional chemical treatments after pulping, such as chlorine, oxygen, or hydrogen peroxide bleaching — combined with steam and water treatments to remove lignin. This results in cleaner, whiter fibers. Unbleached pulp skips this bleaching step and retains much of the wood's original color and composition. The production process is shorter and simpler for unbleached pulp.

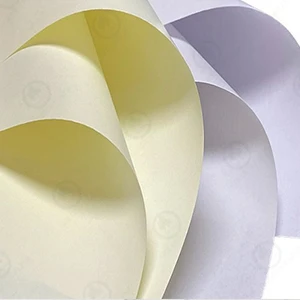

Color

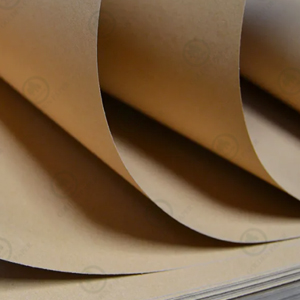

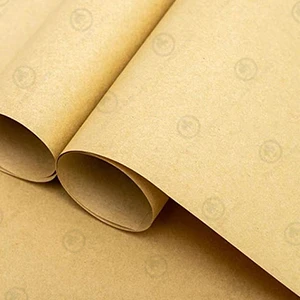

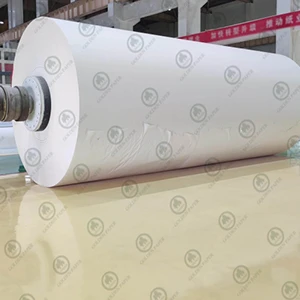

The biggest difference between bleached and unbleached pulp is color. Bleached pulp produces bright white paper, giving it a clean and polished look, ideal for printing, visual presentation, and brand packaging. Unbleached pulp usually results in light brown or beige paper. Though it may not look premium, it conveys a natural, eco-friendly, and sustainable feel, perfect for products emphasizing green values or a vintage style.

Lignin Content and Durability

Lignin is the main reason wood turns yellow over time. Bleached pulp removes almost all lignin, making the paper less prone to yellowing and more durable. This makes bleached pulp suitable for long-term printed materials like books, documents, and archival items. Unbleached pulp retains some lignin, so the paper tends to darken with age. For disposable packaging or short-term use, this isn't a problem and can be more cost-effective.

Environmental Impact

With stricter environmental regulations today, unbleached pulp scores points for sustainability. It uses fewer chemicals during production and reduces wastewater discharge, helping meet international green standards like the EU's Green Packaging Directive and North America's low-carbon certifications. That said, modern bleaching methods like Totally Chlorine-Free (TCF) and Elemental Chlorine-Free (ECF) also offer environmentally friendly options while maintaining whiteness.

Typical Applications

Because of their different properties, bleached and unbleached pulps have distinct uses. Bleached pulp produces smooth, bright paper with excellent print clarity, commonly used for copier paper, Bible paper, wood-free coated paper, and coated art paper. It's also preferred for tissue paper where softness and cleanliness matter.

Unbleached pulp is often used to make strong, economical papers like kraft bags and simple cardboard boxes where high print quality is less critical. If your market prioritizes eco-friendliness or sustainability, unbleached pulp paper is a better fit.

Conclusion

Now you know the key differences between bleached and unbleached pulp and can decide which suits your paper needs best. If you have any questions or want to explore a wide range of paper products, contact Golden Paper. With over 20 years of experience in paper manufacturing, we're ready to support your business. Visit our website or reach out directly for more information!

FAQ

Q: Does unbleached pulp lower paper quality?

A: Not at all. Unbleached pulp simply retains lignin, but it doesn't mean the paper is weaker. For strong, durable, and cost-effective packaging, unbleached pulp is often the better choice.

Q: Is the bleaching process harmful to the environment?

A: Traditional bleaching had environmental risks, but our factory uses ECF and TCF processes that significantly reduce environmental impact.

GOLDEN PAPER

GOLDEN PAPER

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  tr

tr  id

id